Description

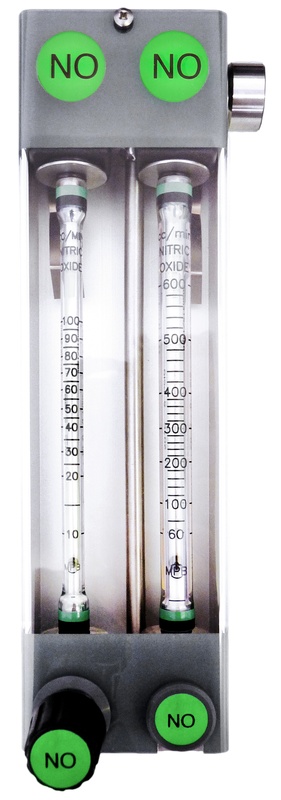

MPB SERIES 640S and 1040S DUAL TUBE FLOWMETER FEATURES

- DIRECT READING OF INSTANTANEOUS FLOW RATES

- WIDE RANGE OF STANDARD FLOW RANGES

- EASY TO READ SCALES

- FRICTIONLESS, HENCE LOW HEAD LOSS

- 6040S: 56MM, 1040S: 93mm TUBE LENGTH

- STANDARD OR CUSTOMISED FLOW SCALES

- VALVED, OR NON-VALVED VERSIONS

- REAR FACING CONNECTIONS

- STAINLESS STEEL CONNECTIONS

- POLYCARBONATE SAFETY COVER

- MINIMAL MAINTENANCE

- REAR OF PANEL MOUNTING KIT AVAILABLE

- LONG SERVICE LIFE

- ALARM VERSIONS AVAILABLE (1040 ONLY)

- EASY TUBE REMOVAL IN-SITU

SPECIFICATION

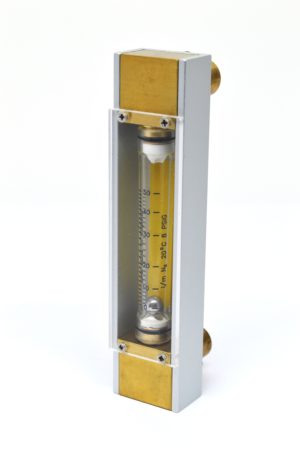

Chassis: Anodised aluminium to BSEN12373/AA25

End Blocks: Stainless Steel

Process Connections: ⅛” BSPPF, or ⅛” NPTF

Cover: Polycarbonate

Seals: Viton, Nitrile, or EPDM

Metering Tube: Borosilicate glass

Scale: Permanently fired black ceramic

Ball Floats: Glass, Stainless steel, Ruby, Tungsten

Plumb Bob Floats: Anodised aluminium, Stainless Steel

Weight: 640s: 400 grams, 1040s: 450 grams

Maximum Working Pressure: Gas: up to 20 bar g (non-shock), Liquid: up to 20 bar g (non-shock)

Maximum Working Temperature: 600C Nitrile, 1000C Viton

Accuracy: ± 5% FSD for predicted scales, ± 3% FSD for calibrated scales